Disposable biodegradable tableware will become a trend in the future

In 1986, foam tableware first began to be used on China's railways. By the beginning of the 21st century, foam lunch boxes had become the mainstream disposable tableware. There are serious problems with the production, use and recycling of disposable foam tableware. Some foaming agents used in the production process will destroy the atmospheric ozone layer, and some have serious hidden dangers; improper use at high temperatures can easily produce substances harmful to human health; carelessly discarding after use can cause serious environmental pollution; being buried in the soil can cause serious environmental pollution. It is difficult to degrade, will cause pollution to soil and groundwater, and is difficult to recycle. Disposable foam tableware was later restricted.

Around 2003, some domestic manufacturers began to launch PP injection molded disposable tableware. Most of them use imported machine molds. In the early days, export was the mainstream of the market. With the development of the Internet and the rise of takeout platforms, PP lunch boxes have gradually exposed their limitations. They may overflow and not be insulated during transportation. Random discarding of PP lunch boxes can also cause serious environmental pollution; it is difficult to degrade when buried in the soil. Under the "plastic ban/restriction" policy, such lunch boxes are also seeking breakthroughs and developing in the direction of environmental protection.

The development of my country's pulp molding industry started in the 1980s and lasted until 2000. It was always in its infancy. In 2001, my country successfully joined the World Trade Organization. Domestic pulp molding enterprises developed rapidly, and the production process, technology and equipment took on a new look. Various types of pulp molded products appear. Since 2020, my country's "plastic ban/restriction" policy has been gradually implemented, and the pulp molding industry has been in a stage of rapid development since 2020.

The raw materials of pulp molded products come from a wide range of sources, and most of the main raw materials are herbal plant fibers, such as reeds, wheat straw, rice straw, bagasse, bamboo, etc. At present, domestic pulp mills that use reed, bagasse, bamboo, wheat straw and other grass fibers as the main raw materials have their own pollution control systems. In terms of raw materials, paper molded products have completely embarked on a road model of "centralized pulping and decentralized production", not only does it have no environmental pollution problems, but it can also obtain more reliable raw material guarantees. Among them, bamboo is the best raw material. Bamboo grows quickly, has no residues of pesticides and fertilizers, and has a natural fragrance. Bamboo is a renewable, compostable resource that has a variety of applications in packaging.

The production technology of pulp molded products is simple, and there are basically no pollution sources during the production process, which meets the requirements of environmentally friendly production. In addition, the pulp molding production equipment is highly domestically produced, which is very conducive to project promotion and application.

Pulp molded products have a wide range of applications, large market capacity, and rich potential to be tapped. Their products can be widely used in electrical appliance packaging, planting and seedling cultivation, medical utensils, catering utensils, and fragile product liners. A compatible pulp The molding production line can produce a variety of products with different uses by simply improving and replacing the molds. Its diversified functions and recyclability make other similar products unmatched.

Pulp molded tableware is an important branch of pulp molded products. It is easy to recycle, can be reused, and is self-degradable. It originates from nature and returns to nature. It is a typical pollution-free, degradable, green and environmentally friendly product, which is very in line with today's era. The requirement to use pulp molded products not only helps save the environment and mitigate climate change, but also extends human life.

As people's awareness of environmental protection and health continues to strengthen, environmentally friendly tableware will certainly be able to replace traditional disposable plastic tableware in the future.

Box With T buckle

Box With T buckle C31-0056-A

C31-0056-A C31-0057-A

C31-0057-A C31-0060-A

C31-0060-A C31-0080-A

C31-0080-A C31-0090-A

C31-0090-A C31-0091-A

C31-0091-A C31-0930-A

C31-0930-A C31-0940-A

C31-0940-A C71-3970-A

C71-3970-A C31-0057-B

C31-0057-B C31-0060-B

C31-0060-B C31-0930-B

C31-0930-B C71-3970-B

C71-3970-B Mult-Part Box

Mult-Part Box C31-0071-A

C31-0071-A C31-0073-A

C31-0073-A C71-3970-A

C71-3970-A C71-3980A

C71-3980A C31-0070-B

C31-0070-B C31-0073-B

C31-0073-B C71-3980-B

C71-3980-B Square Box

Square Box Box Without T buckle

Box Without T buckle C31-0070-A

C31-0070-A C31-0075-A

C31-0075-A C31-2890-A

C31-2890-A C31-3130-A

C31-3130-A C71-4300-A

C71-4300-A C31-2890-B

C31-2890-B One Part Box

One Part Box C31-0950-A

C31-0950-A C31-0950-B

C31-0950-B Cake Bread Snack Tray Series

Cake Bread Snack Tray Series C71-0020-A

C71-0020-A C71-0100-A

C71-0100-A C71-0380-A

C71-0380-A Fruit And Vegetable Tray Series

Fruit And Vegetable Tray Series C71-0490-A

C71-0490-A Sushi Tray Series

Sushi Tray Series C71-2930-A

C71-2930-A C71-2940-A

C71-2940-A C71-2990-A

C71-2990-A Small Round Plate Series

Small Round Plate Series C51-0030-A

C51-0030-A C51-0850-A

C51-0850-A C51-0031-A

C51-0031-A Middle Round Plate Series

Middle Round Plate Series C51-0250-A

C51-0250-A Big Round Plate Series

Big Round Plate Series C51-1790-A

C51-1790-A C51-1740-A

C51-1740-A C51-0621-A

C51-0621-A Bigger Bowl

Bigger Bowl C11-2020-A

C11-2020-A C11-2021-A

C11-2021-A C11-2022-A

C11-2022-A C11-2022-B

C11-2022-B Middle Bowl

Middle Bowl C11-0040-A

C11-0040-A C11-1430-A

C11-1430-A C11-2015-A

C11-2015-A C11-2016-A

C11-2016-A C11-0040-B

C11-0040-B C11-0040-B - PET

C11-0040-B - PET C11-1430-B

C11-1430-B C11-2015-B-PET

C11-2015-B-PET Small Bowl

Small Bowl C11-0050-A

C11-0050-A C11-1420-A

C11-1420-A C11-1421-A

C11-1421-A C11-1422-A

C11-1422-A C11-1422-B

C11-1422-B Bagasse Lunch Boxes

Bagasse Lunch Boxes G71-3982A

G71-3982A G22-0061A

G22-0061A Bagasse Food Plates

Bagasse Food Plates G51-0030A

G51-0030A G51-0020A

G51-0020A Bagasse Bowls

Bagasse Bowls TM-C006

TM-C006 Bagasse Cups And Cutlery

Bagasse Cups And Cutlery G11-0051A(W)

G11-0051A(W) G11-0052A(W)

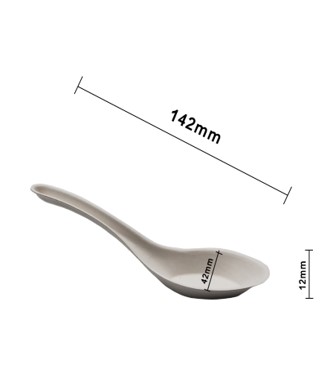

G11-0052A(W) G01-0013D/C/S

G01-0013D/C/S