Kev sib xyaw ntawm cov txheej txheem laminating thiab pulp molding cov khoom siv pov tseg

Tom qab txheej txheej zaj duab xis txheej yog ua ke nrog lub pulp moldingcov khoom siv pov tseg tableware , nws tuaj yeem pab cov khoom siv pov tseg xyoob ntoo kom txo tau cov pa permeability ntawm cov khoom hauv cov txheej txheem siv tiag tiag, thiab kev txuag hluav taws xob yog siab dua thiab lub sijhawm txuag hluav taws xob ntev dua. Tom qab lubxyoob pulp pov tseg tablewareyog them nrog zaj duab xis, cov dej tsis zoo thiab tiv thaiv roj thiab tiv thaiv adhesion muaj peev xwm yuav zoo dua.

1. Zaj duab xis txheej tshuab

Laminating txheej txheem yog hais txog cov txheej txheem uas cov zaj duab xis sib txawv ntawm cov ntaub ntawv sib txawv yog softened los ntawm cua sov los tsim cov pos hniav thiab tom qab ntawd ua ke nrog rau saum npoo ntawm cov pulp molding khoom los ntawm lub tshuab nqus tsev adsorption. Lub hom phiaj tseem ceeb ntawm cov txheej txheem yog kaw tag nrho cov qhov ntawm qhov nro ntawm lub pulp molding, kom cov khoom tsis permeable, kom cov khoom zoo dua nyob rau hauv cov nqe lus ntawm kev txuag tshav kub thiab khoom noj khoom haus tsis-stickiness!

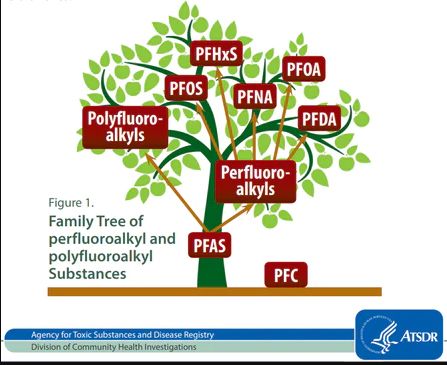

2. Lub ntsiab membrane hom yog PE, PET, CPET, PP, PBAT, PLA thiab lwm yam.PBAT thiab PLA belongs rau hom nrov tam sim no, vim tias ob daim nyias nyias tuaj yeem degraded, thiab covcompostableCov yam ntxwv ntawm pulp molding zoo ib yam, yog li lawv nyiam los ntawm cov teb chaws Europe thiab Asmeskas!

3. Cov kauj ruam tseem ceeb ntawm zaj duab xis txheej raupov tseg tableware

Cov khoom tsis raug muab tso rau hauv cov pwm, thiab cov pwm raug xa mus rau hauv qab ntawm lub qhov cua sov los ntawm txoj siv conveyor lossis lub log. Nyob rau lub sijhawm no, cov yeeb yaj kiab yuav tsum tau them yog txiav tawm ntawm sab saum toj ntawm pwm thiab hauv qab ntawm lub qhov cua sov tom qab lub teeb liab kis tau tus mob pwm nyob rau hauv qhov chaw. Lub sijhawm no, cov yeeb yaj kiab sib xyaw yog rhuab kom muag muag thiab qhib lub tshuab nqus tsev adsorption. Cov zaj duab xis sib xyaw yog absorbed rau saum npoo ntawm cov khoom los ntawm lub tshuab nqus tsev los ntawm qhov sib txawv ntawm cov pwm thiab covpulp molding tablewarekhoom , thiab cov cua kub txuas ntxiv mus kom txog rau thaum lub adsorption yog tag nrho cov xim thiab cov cua kub yog nres. Tom qab cov zaj duab xis sib xyaw ua ke nrog cov khoom siv pulp molding, lub cutter sab saum toj yuav txiav tawm cov yeeb yaj kiab ntau dhau ntawm cov pwm, thiab cov khoom nrog cov yeeb yaj kiab yuav txuas ntxiv mus raws txoj siv conveyor kom txog thaum nws mus txog qhov chaw txiav. Tom qab mus txog qhov chaw txiav, cov khoom yuav raug punched los ntawm cov pwm txiav, thiab cov khoom siv ntau dhau thiab cov yeeb yaj kiab yuav raug txiav tawm ua ke.

4. Zaj duab xis rov ua dua tshiab

Qee cov yeeb yaj kiab sib xyaw ntawm cov khoom coated tuaj yeem degraded thiab qee qhov tsis tuaj yeem degraded, yog li kev sib cais me ntsis yuav tsum tau tshwj tseg thaum siv zaj duab xis coated, thiab cov yeeb yaj kiab tuaj yeem raug cais tawm ntawm cov khoom siv pulp molding tom qab siv, thiab cais raws li rau qhov yuav tsum tau ua dua tshiab. Cov zaj duab xis degradable tuaj yeem ua tiav synchronously nrog cov khoom siv pulp molding kom nrawm degradation los ntawm qhov chaw ntub dej thiab txo cov pa phem ib puag ncig.

Box nrog T buckle

Box nrog T buckle C31-0056-A

C31-0056-A C31-0057-A

C31-0057-A C31-0060-A

C31-0060-A C31-0080-A

C31-0080-A C31-0090-A

C31-0090-A C31-0091-A

C31-0091-A C31-0930-A

C31-0930-A C31-0940-A

C31-0940-A C71-3970-A

C71-3970-A C31-0057-B

C31-0057-B C31-0060-B

C31-0060-B C31-0930-B

C31-0930-B C71-3970-B

C71-3970-B Multi-Part Box

Multi-Part Box C31-0071-A

C31-0071-A C31-0073-A

C31-0073-A C71-3970-A

C71-3970-A C71-3980A

C71-3980A C31-0070-B

C31-0070-B C31-0073-B

C31-0073-B C71-3980-B

C71-3980-B Square Box

Square Box Box tsis muaj T buckle

Box tsis muaj T buckle C31-0070-A

C31-0070-A C31-0075-A

C31-0075-A C31-2890-A

C31-2890-A C31-3130-A

C31-3130-A C71-4300-A

C71-4300-A C31-2890-B

C31-2890-B Ib Ntu Box

Ib Ntu Box C31-0950-A

C31-0950-A C31-0950-B

C31-0950-B Ncuav mog qab zib ci ncuav qab zib tais Series

Ncuav mog qab zib ci ncuav qab zib tais Series C71-0020-A

C71-0020-A C71-0100-A

C71-0100-A C71-0380-A

C71-0380-A Txiv Hmab Txiv Ntoo Thiab Zaub Tais Series

Txiv Hmab Txiv Ntoo Thiab Zaub Tais Series C71-0490-A

C71-0490-A Sushi Tais Series

Sushi Tais Series C71-2930-A

C71-2930-A C71-2940-A

C71-2940-A C71-2990-A

C71-2990-A Me Round Phaj Series

Me Round Phaj Series C51-0030-A

C51-0030-A C51-0850-A

C51-0850-A C51-0031-A

C51-0031-A Nruab nrab Round Phaj Series

Nruab nrab Round Phaj Series C51-0250-A

C51-0250-A Loj Round Phaj Series

Loj Round Phaj Series C51-1790-A

C51-1790-A C51-1740-A

C51-1740-A C51-0621-A

C51-0621-A Lub tais loj dua

Lub tais loj dua C11-2020-A

C11-2020-A C11-2021-A

C11-2021-A C11-2022-A

C11-2022-A C11-2022-B

C11-2022-B Middle Bowl

Middle Bowl C11-0040-A

C11-0040-A C11-1430-A

C11-1430-A C11-2015-A

C11-2015-A C11-2016-A

C11-2016-A C11-0040-B

C11-0040-B C11-0040-B - PEB

C11-0040-B - PEB C11-1430-B

C11-1430-B C11-2015-B-PET

C11-2015-B-PET Lub tais me me

Lub tais me me C11-0050-A

C11-0050-A C11-1420-A

C11-1420-A C11-1421-A

C11-1421-A C11-1422-A

C11-1422-A C11-1422-B

C11-1422-B Bagasse Noj su Boxes

Bagasse Noj su Boxes G71-3982A

G71-3982A G22-0061A

G22-0061A Bagasse Zaub Mov

Bagasse Zaub Mov G51-0030A

G51-0030A G51-0020A

G51-0020A Bagasse Tais

Bagasse Tais Qauv TSIS MUAJ: TM-C006

Qauv TSIS MUAJ: TM-C006 Bagasse khob thiab Cutlery

Bagasse khob thiab Cutlery G11-0051A (W)

G11-0051A (W) G11-0052A (W)

G11-0052A (W) G01-0013D/C/S

G01-0013D/C/S